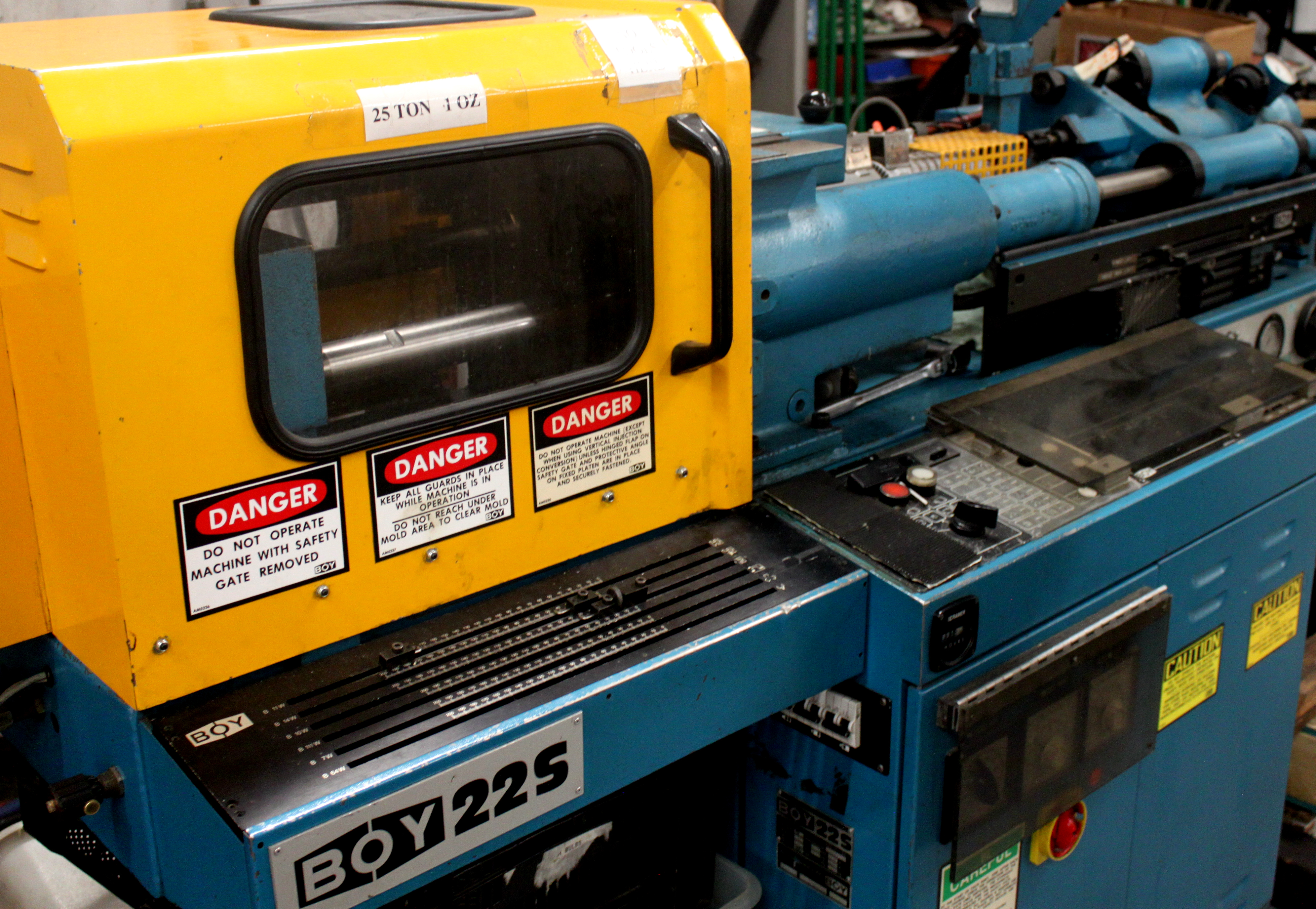

Injection molding is the most popular method of making plastic molded parts.

Injection Molding has the advantage of quality parts produced in high production runs at low cost.

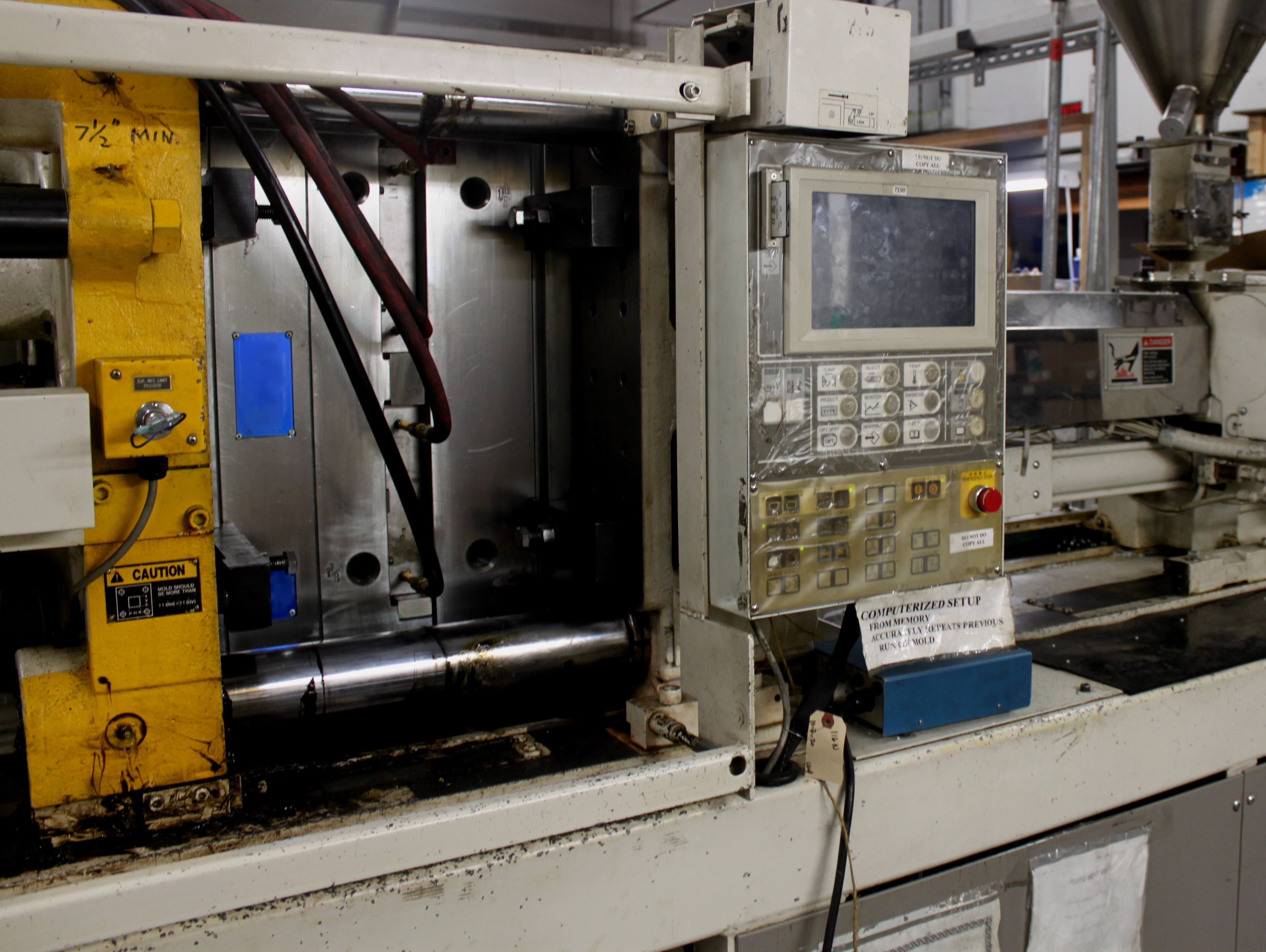

While the plastic pellets are traveling through the barrell they are heated and melted. At the appropriate moment the molten plastic is rapidly “injected” at high pressure into a precision closed mold.

The plastic then cools and solidifies in the mold. The mold then opens and the plastic part or parts are ejected from the mold.

Cycle times for producing parts can typically be from 40 to 60 seconds. Plastic table ware can run as fast as 4 seconds.

Most molds are single cavity (produces one part each cycle). If the mold has 200 cavities (makes 200 parts in one cycle) and cycles in 4 seconds then the production is 200 parts in 4 seconds or 3200 parts a minute.

If you notice the number on the back of plastic table ware next time you are at a fast food place that tells you which cavity the part came from. The little round circles are from the ejector pins.

Can you figure out where the plastic was injected into the cavity?

That is called the gate and is normally at the end of the handle.

Molds / Tooling:

Molds come in a large variety of designs and are typically expensive.

Reiff Injection supplies local, domestic and foreign molds.

Each source has its own advantages and we tailor the mold souce to the customer desires and needs.

The mold shown above is what is called a stripper plate mold because the plate shown in yellow “strips” the red part off of the “core”.

Molds are usually ejector pin type. The parts from those molds typically have little round circles on the “back” where the ejector pins are located.

Styles include:

Method of filling cavity:

- Hot runner molds

- Sprue Gated

- Sprue and runner

Base style:

- MUD base

- Three plate

- Two plate

Core:

- Hydraulic core pull

- Slide core pull

- Rotated core

Insert:

- Hand load insert

- Insert fixture

- Automatic loading

Ejection method:

- Ejectors

- Stripper plate

- Drag link

- Manual (rarely used)